Moth-eye nanostructures make good anti-icing coatings

03 Sep 2020 Isabelle Dumé

Researchers in Vietnam have developed a transparent nanostructure with anti-icing properties that could keep objects such as aircraft wings and wind turbines ice-free in cold, damp conditions. The material, which is inspired by the structure of moth eyes, consists of a quartz substrate coated with a monolayer of nano-sized polystyrene beads. The ensemble is then covered with a flat, insulating layer of paraffin.

On cold days and at high altitudes, water vapour in the air transforms directly into solid ice, forming a thin coating on exposed surfaces. This coating reduces the lift of aircraft wings, blocks moving parts in ships and turbines, and sometimes causes serious motor vehicle accidents as well as damage to infrastructure such as electricity transmission systems.

There are two main approaches to improving the anti-icing properties of surfaces in these conditions. The first, active approach is to remove the ice using an external source of energy, such as heat. The second, passive approach uses physiochemical methods to modify the surface – with superhydrophobic materials, for example – so that it repels water.

SLIPs: an advanced anti-icing strategy

More recently, a new variant of the passive strategy has emerged: applying a coating to icing-prone objects that forms a defect-free liquid interface with the ice. Such coatings are known as slippery liquid-infused porous surfaces (SLIPs), and one way of making them is to cover a porous structure with a low-surface-tension lubricant that is immiscible in water, resists humidity and self-heals after ice treatment.

While the SLIPS studied to date have produced some good anti-icing results, none of them can prevent icing permanently because their lubricant layer degrades through evaporation and during de-icing. Physicists Nguyen Ba Duc of Tan Trao University and Nguyen Thanh Binh of Thai Nguyen University of Education sought to avoid this problem by creating a SLIP based on a nanostructure that mimics the structure of moth eyes, which are inherently ice-phobic.

In their experiments, Ba Duc and Thanh Binh used a plasma etching process to deposit polystyrene nanobeads onto a quartz substrate. This process produced a uniform structure of protrusions shaped like truncated cones with heights of 500 nm and top diameters of around 70 nm, as revealed in scanning electron microscopy measurements. The researchers then added paraffin wax to an n-hexane solution and coated the top of their nanostructure with the mixture. As a control experiment, they also applied the same thickness of paraffin wax/n-hexane coating to a bare quartz substrate.

Measuring adhesion forces

Next, the researchers attached their samples to a thermoelectric cooling module and gently placed a 5 μl droplet of deionized water onto the sample surface. After cooling the system down to -20°C, they used a load cell to measure how strongly an ice drop adhered to the freezing surface. They did this by moving the cell at a speed of 50 μm/s, which slowly pushed the ice droplet sideways until it detached completely. The force exerted on the cell could then be computed, and the researchers took the maximum force recorded to be the droplet’s adhesive strength.

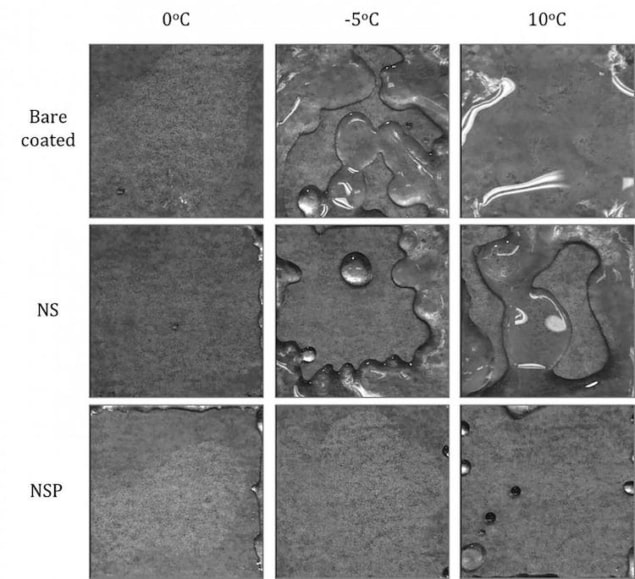

Ba Duc and Thanh Binh also used a high-speed camera to record the icing process and determine the time it took for the entire water droplet to freeze solid. Another camera monitored changes to the interface between the water droplet and the surface. Finally, the researchers performed a “freezing rain” test in which they sprayed cold water droplets (maintained at temperatures of 0.5°C) ranging from 5 μl to 50 μl in size onto surfaces at 0°C, -5°C, -10°C and -15°C.READ MORE

The results for the nanostructured surface confirmed its outstanding anti-icing performance relative to the control surface. The researchers also say that the hydrophobic nature of the paraffin layer proved key to the performance of the new structure in both the static (water droplet) and dynamic (freezing rain) experiments.

Delayed heat transfer

The researchers chose paraffin as their coating material because it is water-repellent and has a low thermal conductivity. When the paraffin coats the top of the nanostructured quartz substrate, the substrate becomes isolated from its environment, preventing heat from being transferred away. Air pockets trapped inside the nanostructure contribute to delayed heat transfer too, Ba Duc and Thanh Binh explain, adding that this extra insulation also increases the freezing time of any attached water droplets.

As well as anti-icing applications in industry and transport, the superhydrophobic nanostructured coated paraffin material might be suitable for applications such as eye glasses, Ba Duc says. This is because it is highly transparent and has anti-reflective properties, just like moth eyes. The researchers also report that the material is mechanically stable, and the paraffin-coated layer can easily be recovered after tests simply by heating it.

The new anti-icing structure is detailed in AIP Advances.

from physicsworld.com 7/9/2020

Δεν υπάρχουν σχόλια:

Δημοσίευση σχολίου