Phase-change memory gets efficiency boost

14 Oct 2021 Isabelle Dumé

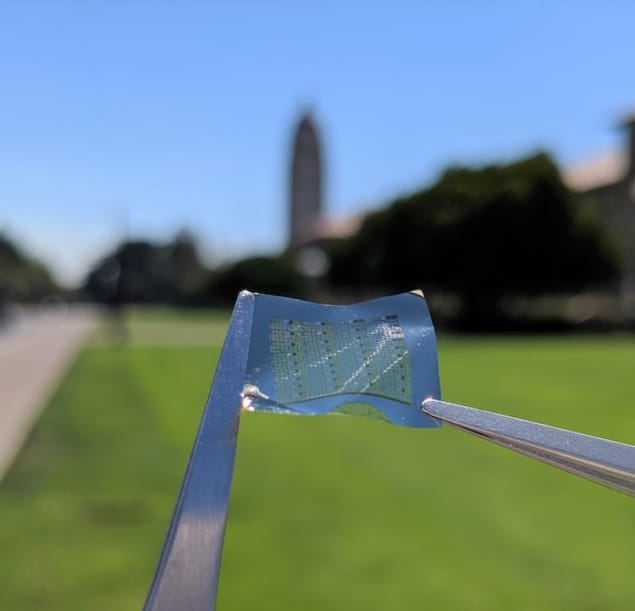

A new phase-change memory device that uses much less energy than its predecessors could help meet the world’s increasing demand for digital information storage. The device, which was developed by researchers at Stanford University in the US, is made from a so-called superlattice material placed on a flexible/bendable substrate, and it boasts a switching current density of just 0.1 MA/cm2 – making it 100 times more efficient than other memory types of its kind.

The volume of digital information produced worldwide is currently doubling every two years. By 2025, it could reach a staggering 160 zettabytes (a zettabyte is 1021 bytes, or 1 trillion gigabytes). Phase change memories (PCMs), which rely on the ability of certain materials to switch between a crystalline state that conducts electricity well and an amorphous state that does not, could help address this demand. However, switching between the “1” and “0” states in a PCM tends to require relatively high currents, as the material must be heated before it can change phase. This is true regardless of whether the PCM is placed on a rigid substrate such as silicon or a flexible one such as plastic.

Ultralow programming current density

In the latest work, a team led by Eric Pop succeeded in creating a PCM with an ultralow switching current density. The new PCM’s low power use makes it especially attractive for applications related to the Internet of Things (IoT) and mobile devices, both of which often rely on batteries or energy-harvesting systems.

The researchers made their memory devices directly on a flexible polyimide substrate. The phase change material they used was a superlattice made of alternating thin layers of antimony telluride and germanium telluride. They confined this material stack in a “pore” surrounded by insulating aluminium oxide. They then contacted the top and bottom of the structure with titanium nitride metal electrodes.

More energy-efficient on a flexible substrate

As well as its ultralow current density, Pop and colleagues note that their PCM also has another advantage: each step of its fabrication takes place at temperatures below 200 °C, making it compatible with a variety of flexible plastic substrates. This is important because without a good insulating layer, the electrical pulses used to switch the PCM could cause other electronic components in a device to heat up and become less efficient.

“The superlattice material combined with the confined pore-cell design play a key role in this aspect,” Pop explains, “but we found that the very low thermal conductivity of the flexible substrate also helps. In other words, the memory becomes more energy-efficient on a flexible substrate as compared to a conventional silicon substrate.”

Smart applications

The new PCM might be used in any flexible electronic device that requires low-power, non-volatile data storage, Pop tells Physics World. One example is smart sensors for the IoT, which process and store data locally before sending it to the cloud. Such devices could be useful for environmental monitoring, food packaging analysis and electronic skin for robotics as well as biomedical sensing with on-skin or implantable devices. This type of PCM could also be useful in more general-purpose flexible processors, such as those demonstrated recently by ARM and PragmatIC, or for in-memory computing on flexible substrates.READ MORE

The Stanford team is now exploring other superlattice materials and new designs to further improve the energy-efficiency and thermal stability of their flexible PCM. They say they might achieve this by optimizing the sidewalls of the structure and by reducing the diameters of the pore-like memory cells. “We are also looking into superlattice materials with an even lower thermal conductivity and higher thermal stability to improve the energy-efficiency of our memories,” Pop says.

The new PCM is detailed in Science.

FROM PHYSICSWORLD.COM 14/10/2021

Δεν υπάρχουν σχόλια:

Δημοσίευση σχολίου